FTTH Drop Cable Production: How the Manufacturing Process Works

Surprising fact: more than seventy percent of new U.S. broadband builds now rely on fiber networks that need high-precision manufacturing to achieve required performance.

Shanghai Weiye OFC Equipment manages full-cycle fiber secondary coating line manufacturing, from choosing brand fibers like Fujikura or Corning® SMF-28e to comprehensive test documentation that deliver 100% QA.

Our drop cable designs suit overhead, underground, and direct-buried installation, with LSZH, PVC, and polyethylene (PE) jacket options and configurations from 1–4 cores. We provide OS1/OS2 and multimode OM2–OM4 grades plus ITU-T G.652D and ITU-T G.657 variants, Pantone sheath colors, and custom logo printing.

Automated machines and high-precision equipment stabilize line speed and repeatability high. Typical lead times run four to five days for orders under 100 km and 7–10 days under 500 km, with an min. order of 1 km and warranty for free replacement on quality issues.

Continue to learn how our materials, tests, and support combine to lower lifecycle cost and align the product to your network needs.

- Shanghai Weiye OFC Equipment delivers end-to-end manufacturing and lab testing for United States projects.

- Multiple jacket choices and optical grades support varied installation environments.

- Automated production lines deliver stable quality and stable optical performance.

- Quick lead times, low minimums, and brand fiber options support reliable procurement planning.

- Complete reports and after-sales warranty support product reliability and compliance documentation needs.

Expert FTTH manufacturing by Shanghai Weiye OFC Equipment

When deadlines and performance are critical, Shanghai Weiye OFC Equipment provides tailored drop solutions with complete test documentation.

As a dedicated manufacturer, Shanghai Weiye OFC Equipment pairs purpose-built equipment with tight material control. We offer customized service and products for residential and MDU rollouts. Every order includes 100% quality assurance and complete test reports.

Our lab performs high heat, salt-fog, and vibration tests to validate durability. Jacket options cover LSZH, PVC, and PE. Designs offer bow-type flat and figure-8/self-supporting styles and support brand fibers such as Fujikura and Corning® SMF-28e.

- Documented line control and in-process checks for shipments with audit trails.

- Engineering support for specs, trials, and ramp to volume.

- Modern fixturing and calibration reduce variability so every cable meets operator standards.

How We Produce FTTH Cable

At Shanghai Weiye OFC Equipment, manufacturing steps are matched to network specs, combining brand fiber choices with rigorous test routines.

Optical fiber selection and brand options

We align Fiber coloring machine to bend radius, loss, and install environment. Options include OS1/OS2 and OM2–OM4 and G.652D and G.657.A1/A2 per ITU-T. Brand fibers such as Fujikura® and Corning® SMF-28e are available to satisfy sourcing standards.

Strength member integration

Strength members use dielectric FRP or galvanized steel wire. FRP is ideal where non-conductivity is necessary. Steel wire provides tensile strength for longer aerial spans and grounding needs.

Jacket Options and Control

Jacket options include LSZH for flame/smoke safety, PVC for flexibility, and PE for UV/moisture resistance outdoors. Tight process control of extruder temperature and capstan speed stabilizes line speed and critical dimensions.

| Member | FRP | Metallic Steel |

|---|---|---|

| Use case | Electrical isolation | High-tension aerial runs |

| Key benefit | Light, non-corrosive | High strength |

| Installation note | Easier terminations | Bonding/grounding required |

Testing & Verification

Inline geometry/concentricity checks operate in-line. Final optical tests confirm attenuation and reflectance. Each order includes a 100% test report and lab results from high-temperature, salt fog, and vibration tests to confirm handling for drop terminations and field use.

Typical lead times are under 100 km in 4–5 days and 7–10 days for < 500 km. Material lot records and FAI approvals provide traceability and compliance for U.S. projects.

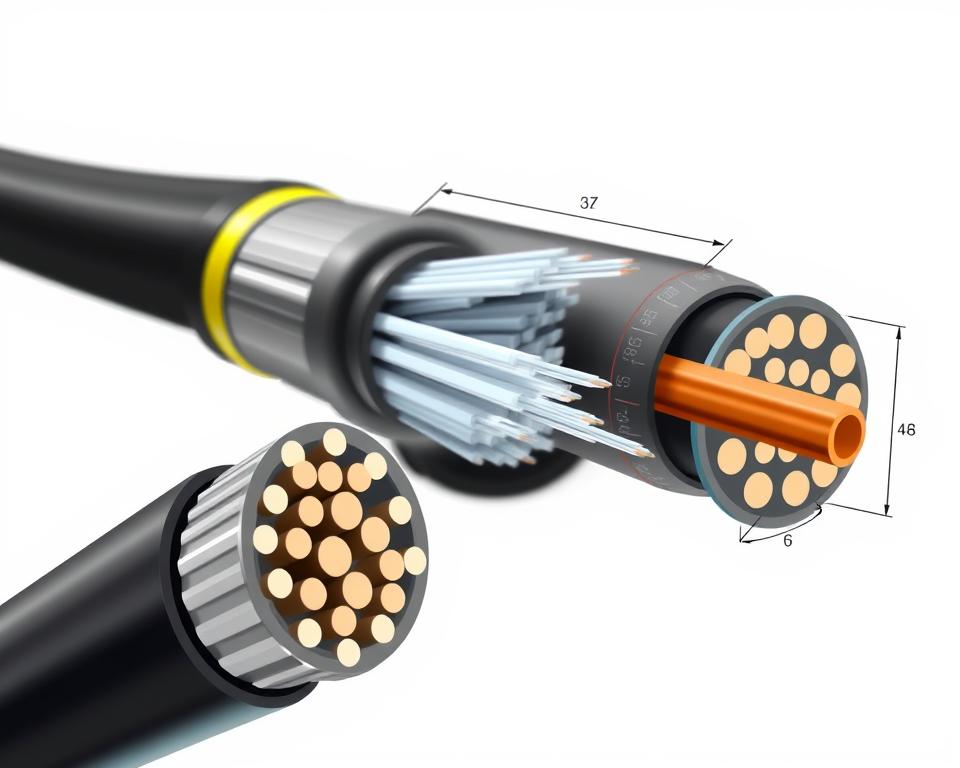

FTTH Drop Designs We Build

Shanghai Weiye OFC Equipment offers a focused portfolio of drop designs that cover tight indoor routes and exposed aerial spans. Each option combines tested materials with field-termination geometry and consistent optical performance.

The flat bow-type drop keeps a small footprint for risers/ducts. It reduces bend loss for simple routing in hallways and MDUs.

Aerial Self-Supporting Options

Self-supporting FTTH drop designs use a support messenger to handle tension. Choose FRP (dielectric) for electrical isolation or steel wire when bonding/grounding and extra tensile strength are required.

Layouts & Strength Members

We offer both dielectric and metallic strength member configurations to meet safety/EMI requirements. Center loose tube and flat unitube types balance crush resistance and fiber ribbone line for quick termination.

Indoor vs Outdoor Jackets

Jacket choices include LSZH for indoor flame/smoke compliance and PE for outdoor durability. Each series is qualified for mechanical and optical quality before shipment.

| Type | Application | Strength element | Jacket |

|---|---|---|---|

| Bow-type flat | Indoor risers and MDUs | Dielectric FRP | LSZH |

| Self-supporting | Aerial spans | Steel wire or FRP | Polyethylene |

| Central loose-tube | Higher-count builds | Dielectric FRP | LSZH or PE |

| Flat unitube | Low count, quick strip | FRP or steel | LSZH/PE |

Production Assets for Speed and Quality

Automation and sensor-driven feedback at Shanghai Weiye OFC Equipment cut manual handling and increase throughput for patch cord prep.

Our production line uses automated machines that cut/strip drop cords to increase output and reduce operator variability.

The CLX-BPO2 automated stripper uses PLC + photoelectric control. One cycle is ~1.5 s, giving ~20 terminals per minute in production.

Automated cutting and stripping for drop cable patch cords

The equipment strips LSZH and PVC jackets and trims FRP/steel members to precise reserved lengths. Cylinder-driven actuators deliver fast, repeatable motion and minimize downtime.

PLC/photoelectric control for precision and repeatability

PLC logic and photoelectric sensors deliver precise positioning and feedback control. Inline checks update SPC charts so operators can correct trends before defects grow.

| Feature | Spec | Benefit |

|---|---|---|

| CLX-BPO2 | Auto-strip, ~1.5 s cycle | High throughput |

| Actuation | Cylinder-based | Fast/reliable motion |

| Material handling | LSZH & PVC; FRP & steel | Accurate stubs, clean terminations |

| Control | PLC/photoelectric with in-line SPC | Stable quality, reduced rework |

- Automated waste ejection and ergonomic feeders maintain clean workcells.

- Process control plans document calibration and key parameters.

- Combined machines, fixtures, and trained staff help meet FTTH volume goals without compromising accuracy.

What the CLX-BPO2 Adds

The CLX-BPO2 provides industrial-grade strip/trim to our line, reducing cycle time while maintaining consistent prep.

Shanghai Weiye OFC Equipment uses the CLX-BPO2 to raise output and standardize terminal quality. The unit runs at an approximate cycle time of 1.5 seconds, producing around 20 preps per minute in production.

PLC/photoelectric control enable precise detection and repeatable motion. That control helps keep strip lengths and reserved strength stubs within tight tolerances.

Line Speed

Typical operation speed is ~1.5 seconds per cycle. This enables steady throughput under continuous line conditions.

Supported Strip and Stub Lengths

The CLX-BPO2 handles LSZH/PVC with an adjustable jacket strip length from 17.5–35.0 mm. Reserved strength member stubs are adjustable from 7.0–11.0 mm to match common termination hardware.

FRP & Steel Member Handling

The machine cuts FRP/steel strength elements cleanly while protecting adjacent fibers. Customized cutters are available for nonstandard sizes to maintain precision.

- Auto-eject scrap and sensor-triggered start cut idle time.

- Small footprint (L40 × W18 × H18 cm), 50W at 110–220V, and 11 kg weight ease integration into workcells.

- Pneumatic cylinders and closed-loop control boost reliability and lower maintenance interruptions.

| Specification | Value | Benefit |

|---|---|---|

| Cycle | ~1.5 s (~20/min) | Supports high-volume runs |

| Strip lengths (A) | 17.5–35.0 mm | Fits common connector processes |

| Reserved stub (B) | 7.0 to 11.0 mm | Supports termination strength |

| Power & size | 50W @ 110–220V; 40×18×18 cm | Easy integration into existing equipment |

Using this machine, Shanghai Weiye OFC Equipment standardizes terminal prep so field teams get drop parts install-ready. The CLX-BPO2 supports our lines in meeting volume targets without compromising quality.

Tailored Specifications for Your Network

Shanghai Weiye OFC Equipment configures every order to meet your network requirements and simplify field rollout. We combine focused options with predictable schedules so your teams receive ready-to-install products.

Choose 1 to 4 cores with single-mode or multimode fiber. Options include OS1/OS2 plus OM2–OM4 plus G.652D and G.657 variants to match your optics and connector plans.

We match sheath colors to Pantone codes for quick field identification and consistent asset tagging.

Branding and Print Options

Select LSZH/PVC/PE jackets to suit route and safety requirements. Custom print legends and logos support inventory and warranty tracking.

Length options, packaging, and special structures

Standard reel lengths are 1 km, 2 km, and 4 km with tailored reels and packaging to fit storage/handling. Choose bow-type flat or self-supporting designs and steel wire or FRP strength members to meet span and isolation needs.

| Choice | Typical | Benefit |

|---|---|---|

| Length | 1 / 2 / 4 km | Less staging, easier reels |

| Sheath | LSZH, PE, PVC | Indoor/Outdoor fit |

| Structure | Flat bow / Self-supporting | Flexible routing/span |

As a supplier, Shanghai Weiye aligns runs to your schedule and provides docs that detail final specs for easy on-site QA.

QA, Testing & Documentation

Shanghai Weiye OFC Equipment builds checkpoints into production so every item has recorded acceptance data at ship.

Environmental and Mechanical Tests

Our lab conducts elevated-temperature exposure, salt fog corrosion, and mechanical vibration to qualify materials and assemblies. These tests recreate field stresses for indoor/outdoor applications.

100% test reports for every cable

Every fiber optic cable includes a 100% test report that records loss, return loss, and key geometry where applicable. Final QC gates prevent nonconforming shipments before they leave the factory.

Audit Trail and Compliance

Lot/batch records link tests to reels/serials so audits and claims are easy to verify. Documentation uses standard customer templates to speed approvals and inbound inspection.

- Line checks and final inspection prevent field failures and cut warranty events.

- Quality packages include specifications confirmation and formatted data for quick review.

- Ongoing trend analysis inform preventive maintenance and raise long-term reliability.

| Test | Why | Outcome |

|---|---|---|

| Heat exposure | Material stability | Validated heat endurance |

| Salt spray | Corrosion resistance | Outdoor suitability |

| Vibration | Resistance to vibration | Reduced field failures |

Pricing and cost drivers for FTTH drop cable

Budgeting for a drop run starts with fiber and jacket choices and is refined by volume and customization.

Typical prices range broadly—from about $30 to $1,000 per unit—based on fiber grade (G.652/G.657/OM2–OM4), jacket material, length, and design structure.

Materials, Grade, Jacket & Structure

The primary cost drivers are fiber grade, sheath material, and the chosen structure for deployment.

Self-supporting structures and steel members increase material/labor. Custom sheath colors/logos/legends add setup time and impact pricing on small runs.

Order length, volume, and customization impact on price

Longer reels and higher volume orders reduce unit cost. Short runs often include setup charges and higher unit prices.

- Line changeovers and custom tooling extend lead time and add to cost.

- Clear RFQs and line scheduling let Shanghai Weiye OFC Equipment align price quotes to delivery windows.

- Frameworks and indexed pricing stabilize budgets across phases.

| Factor | Effect on price | Recommendation |

|---|---|---|

| Optical grade | Large | Right-size spec to budget |

| Jacket type | Medium impact | Evaluate LSZH vs PE |

| Order length / volume | High impact | Consolidate runs to cut unit cost |

U.S. Lead Times, MOQ & Delivery

Shanghai Weiye OFC Equipment keeps lead times/logistics clear so planners can align staffing and sites. Predictable windows reduce downtime and help control cost when a rollout is underway.

Scheduling & Capacity Planning

Typical production windows run 4–5 days for orders under 100 km and 7–10 days for < 500 km. We schedule line capacity to track your milestones and to keep deliveries on time.

The service team issues production updates and tracking so installation teams can plan arrivals. For tight schedules, we reserve contingency capacity to pull in critical-path orders.

MOQ and Rationale

The MOQ is 1 km. This reflects line setup such as wire and jacket die adjustments that use startup material and generate scrap.

We review your length and staging plans to choose reel sizes that cut waste and handling. Staggered batches can balance inventory holding with more frequent small-site deliveries.

Where and How to Deploy

On-site conditions dictate whether a self-supporting aerial, ducted pull, or direct burial is the best fit for a project.

Aerial vs Duct vs Direct-Buried

For aerial runs, Shanghai Weiye OFC Equipment advises self-supporting designs with appropriate members to control sag and tension for long-term stability.

Duct installations work best with low-friction jackets and crush-resistant constructs so pulling does not damage fibers. PE jackets are common for underground and buried paths where moisture resistance matters.

Direct-buried designs need correct burial depth per local codes and moisture-resistant jackets to protect the fiber core long-term.

Indoor Distribution and ONT

Indoor riser and plenum routes favor LSZH jackets to meet smoke/flame codes. Flat drop cable forms strip clean and present controlled stubs for quick ONT termination.

We guide the choice of steel or FRP (dielectric) strength members based on bonding needs, lightning exposure, and hardware fit. Standardized line prep reduces install time and reduces scrap.

| Deployment | Key design | Installer note |

|---|---|---|

| Overhead | Self-supporting (steel/FRP) | Check tension and messenger hardware |

| Duct | Low-friction jacket, crush resistance | Use pull tape + lubricant |

| Direct-buried | PE with moisture barrier | Follow depth/warning tape codes |

| Indoor | LSZH jacket, tight bend support | Maintain bend radius at wall penetrations |

Our approach delivers a consistent installation across indoor outdoor transitions. That leads to fewer callbacks, faster activations, and stable field performance for your system.

Support from Spec to Service

Our team coordinates testing, scheduling, and installation guidance to avoid surprises in deployment.

Shanghai Weiye OFC Equipment provides engineering support from early requirements through approved drawings and pre-production builds. We deliver documentation templates and clear install notes so field crews share a unified plan.

After-sales service covers rapid response, root-cause analysis, and corrective actions. All products ship with full reports and traceability to help QA acceptance.

- Round-the-clock availability for status and technical support.

- Warranty with free replacement if any quality problems are confirmed.

- Schedule coordination for expedites and urgent changes.

- Configuration control so shipped items match agreed specs consistently.

| Area | Scope | Benefit |

|---|---|---|

| Engineering | Specs + pilots | Reduced field issues |

| Testing | Lab trials & 100% test reports | Traceable quality |

| Service | Fast replace + RCA | Minimized downtime |

Conclusion

Select Shanghai Weiye OFC Equipment for custom drops, quick lead times, and full traceability.

We deliver customized FTTH drop solutions that combine materials with validated manufacturing and lab tests. Every reel ships with a 100% test report and documented trials to support field acceptance in the United States.

A hardened production line, including CLX-BPO2 prep assets, reduces variability and speeds turnaround. Our equipment and machines standardize strip/stub lengths so installers get consistent results at turn-up.

From fiber selection to jacket, printing, and packaging, we balance performance and cost to maximize service life. Dedicated support covers scheduling/logistics/after-sales so your deployment stays on plan.

Contact Shanghai Weiye OFC Equipment to align specifications, timeline, and volume. We stand behind every fiber optic and optic cable shipment with laboratory validation and responsive service.