AMT – Leading MiM Manufacturer in Singapore.

Can a single partner in Singapore handle complicated metal parts for medical and automotive needs without using multiple suppliers? Yes.

As a top MiM producer and contract manufacturing partner in Singapore, AMT – MiM manufacturer blends years of metal injection molding know-how. It adds services to complement this. AMT delivers a seamless MiM process. The workflow transforms feedstock into finished, assembly-ready components.

AMT is here for medical device companies, procurement teams, and buyers of precise components in the Asia-Pacific area. A single source provides precision MiM, value-add machining, cleanroom assembly, and supply chain assistance. This cuts down on handoffs, boosts traceability, and makes for quicker lead times in controlled fields.

Highlight Reel

- AMT is a top MiM producer in Singapore offering end-to-end production.

- The company does metal injection molding along with finishing and putting things together for regulated industries.

- A single source reduces risk and speeds time to market.

- AMT manufactures precise MiM components for medical, automotive, and semiconductor sectors.

- Improved QC, enhanced traceability, and simpler logistics benefit customers.

AMT Overview: Metal Injection Molding Leadership in Singapore

Since 1996, AMT has progressed from a local operation to a premier MiM provider. The company is recognized for comprehensive production support. That experience ensures dependable transitions from prototype to mass production.

Company background and history since 1996

Since 1996, AMT has built precision expertise in Singapore with growth across SEA. OEM partnerships made AMT a trusted MiM name. Ongoing spend in tooling, metrology, and cleanrooms sustains stringent standards.

Core manufacturing capabilities: MiM, CIM, plastic injection molding, CNC and micro molding

Expertise spans MiM and CIM for intricate parts and high-performance ceramic components. Their site also handles micro molding for precise polymer items.

Additional services include CNC machining, finishing, and cleanroom assembly. It positions AMT as a one-stop MiM partner for high-precision demands.

Industries served with emphasis on medical, automotive, consumer, industrial, and semiconductor sectors

AMT works with medical firms on implants, surgical tools, and diagnostics. Auto Tier suppliers trust AMT for precision small parts.

Consumer, industrial, and semiconductor customers rely on AMT for accurate MiM parts. Serving diverse sectors highlights AMT’s versatility.

AMT as a MiM Manufacturer

AMT is a MiM manufacturer based in Singapore. It manufactures complex, finely detailed metal parts at scale. Customers get support across design, tooling, production, and documentation. It streamlines sourcing and shortens the path from prototype to full production.

What the designation means for buyers and OEMs

Working with a qualified MiM manufacturer – AMT provides access to validated MiM technology with tight process control. Controls keep materials consistent, dimensions tight, and high-volume economics favorable. For regulated markets, full traceability, validation evidence, and integrated QMS are key benefits.

Integrated MiM Process Flow at AMT

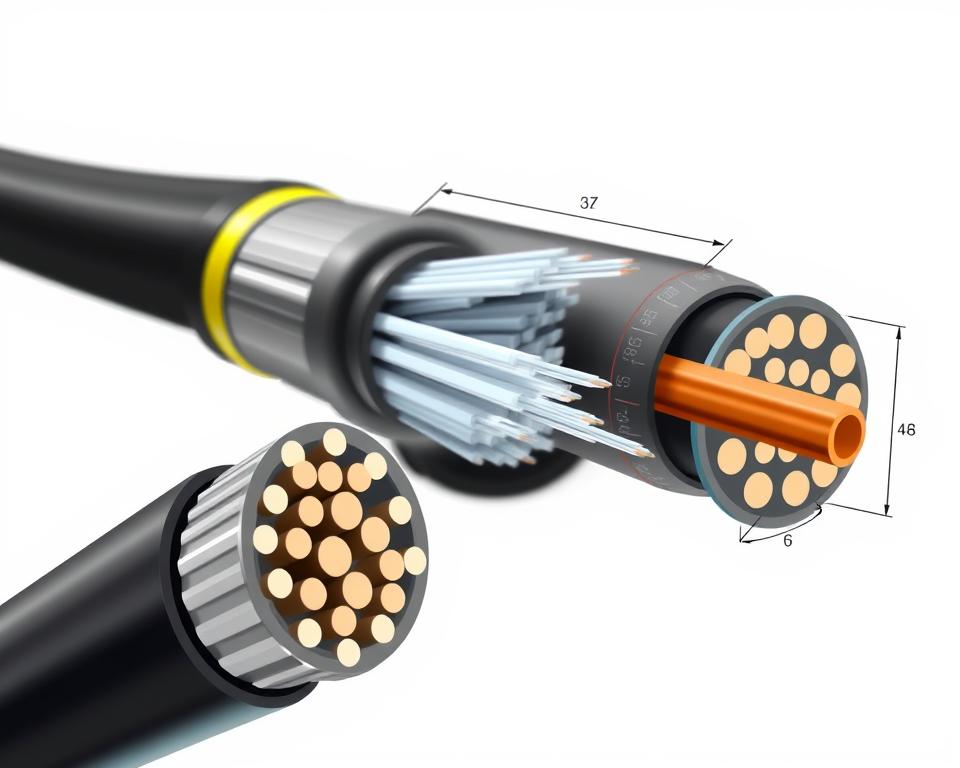

First is feedstock compounding. Metal powders are compounded with polymers to form a uniform blend. Next, injection molds the initial “green” parts. Precision molds (and micro-molding where needed) enable fine features.

Debinding then removes binder (thermal or solvent) while retaining part geometry. Then sintering consolidates and densifies the parts. This step delivers final properties and near-net dimensions. Finally, finishing can include extra machining, thermal treatments, improving the surface, and assembling in cleanrooms for certain needs.

Applications Across Medtech and Industry

AMT manufactures precision MiM components for medical devices. Examples include implantables, micro-implants, and diagnostic components requiring smooth finishes and biocompatible alloys. Automotive and semiconductor applications benefit from tight-tolerance parts with dependable performance.

A key AMT strength is scaling from prototype to mass production. It maintains control of properties and dimensional accuracy. That makes AMT a smart choice for OEMs needing volume, consistency, and top-tier MiM technology. This matters a lot in fields where rules are strict and the demand is high.

AMT’s Medical Manufacturing Credentials and Trade Show Presence

AMT uses trade shows and awards to build trust with medical OEMs and contract makers. At key events, AMT presents quality systems, showcases MiM technology, and discusses regulations with prospects in Singapore and across Asia.

Participation at Medical Manufacturing Asia 2024

At Marina Bay Sands (Sept 11–13, 2024), AMT joined Medical Manufacturing Asia. Medtech engineers, sourcing teams, and regulatory specialists visited their booth. Conversations centered on device manufacturing strategies and next actions.

Recognition: IVAM Marketing Award Asia 2024

AMT received the IVAM Marketing Award Asia 2024, earning the Rhino Trophy and one-year IVAM membership. “Do it right at the start” underscores quality and smart DfM. This recognition strengthens AMT’s standing with medical customers.

Events as a Platform for Reg & Quality

Events enable direct ISO and regulatory conversations. Capabilities highlighted include MiM, precision molding, CNC, and clean assembly. Direct discussions help customers review credentials, validation plans, and supply continuity.

| Event | Date | Key Outcomes |

|---|---|---|

| MMA 2024 | 11–13 Sept 2024 | New partnership talks, regs Q&A, mim tech showing |

| MD&M West 2025 | Feb 2025 | Display of full production, choosing suppliers, better supply chain connections |

| IVAM Marketing Award Asia 2024 | 2024 | Rhino Trophy, 1-year IVAM membership, recognition for DfM communication |

Customers value AMT’s event track record and awards when selecting a MiM supplier. Such recognition indicates expertise, mitigates risk, and fosters qualification discussions with technical teams.

Materials and Production Capabilities

AMT supports a broad material portfolio for medical and industrial needs. Materials include stainless steels, cobalt-chrome, and nickel alloys. They are chosen for their strength and ability to resist corrosion. For parts needing to stay cool or not conduct electricity, we offer ceramic options too.

Material selection and process control safeguard quality. Tuning feedstock and sintering achieves required density/performance. This is crucial for making reliable implants and precision industrial parts.

Our MiM parts feature precise geometry and fine details. Injection enables thin walls and intricate features. This lowers downstream machining. We keep everything within strict medical and semiconductor standards.

At scale, MiM lowers cost and improves speed. Our molding processes are consistent and predictable. It reduces finishing and supports effective inventory planning.

Additional processes further enhance finished components. CNC machining makes surfaces and details perfect. Cleanroom assembly plus precision molding integrates metals and other materials into high-quality assemblies.

AMT is a one-stop shop for mim manufacturing needs. Material science, process discipline, and precise finishing are blended. This lets us meet the high standards our clients expect.

Quality Systems and Supply Resilience

AMT considers its quality management a key strength for medical industries. It blends documentation with practical process control. Buyers trust a MiM partner that understands clinical and safety standards.

Quality systems and certifications

AMT prepares for ISO 13485 and other important medical standards. It uses third-party certifications, internal audits, and training to oversee mim processes. OEMs and suppliers favor partners with consistent compliance and effective CAPA.

Documentation and Traceability

Traceability runs from feedstock through every stage. Batch records and material certs support filings and audits. First article inspections and process control charts confirm mim production’s quality.

MiM Validation Practices

Materials, process, and dimensional validation are included. Full traceability and change history are maintained. This reduces risk during product changes and regulatory submissions.

Supply chain management and single-source benefits

At MD&M West 2025, AMT showcased its integrated services. These included MiM and CNC, among others. Using one mim manufacturer reduces lead times and makes overseeing suppliers easier. It centralizes quality control and minimizes inter-supplier transitions.

Global Reach & Resilience

From Singapore, AMT serves clients in Asia and North America. Attending trade shows helps it build regional partnerships and spread out supply sources. Strong strategies for qualifying suppliers and using multiple sources help keep medical supplies moving without interruption.

Design for MiM Manufacturability at AMT

Choosing the right design shortens lead times and reduces costs in metal injection molding. Early collaboration aligns geometry to MiM constraints. This boosts yield and accelerates validation for med/industrial projects.

Guidelines for Geometry, Thickness, Tolerances

Uniform wall thickness minimizes distortion and stabilizes dimensions. Using fillets at corners improves material flow and lowers stress during debinding and sintering. Minimize sharp corners/undercuts to simplify molds.

Complex parts may benefit from collapsible cores or modular assemblies. That reduces tooling complexity. Working closely with AMT ensures that tooling accounts for shrinkage and fits perfectly.

Cost & Lead-Time from Prototype to Production

Early stages often employ soft tooling for trials. Hard tooling cuts unit cost with higher initial lead time. Planning tool changes early reduces rework and speeds market entry.

AMT advises on scaling from prototype to production with volume/cost in mind. They link materials/design updates to MiM process strategy.

Case examples of redesigns that improved yield and reduced downstream machining

A prior redesign embedded mating features, removing CNC ops and saving time. Yield rose thanks to less handling, lowering scrap and variation. A second case consolidated parts into one MiM component, simplifying supply and inventory.

These examples show that close work with a reliable MiM supplier lowers cost. Supply stability and modern MiM advantages are realized.

Applications & Case Studies

Sectors served include medical, automotive, and industrial. AMT acts as manufacturer and supply partner. They focus on projects needing intricate details and consistent quality.

In the healthcare field, AMT creates parts that go inside the body, tools for surgery, and diagnostic equipment casings. Components are biocompatible and produced in clean environments. Showcased at Medical Manufacturing Asia 2024 and MD&M West 2025.

Automotive/industrial outputs include high-strength fasteners, valve parts, sensor covers, and durable components. Near-net shaping reduces machining, lowers waste, and speeds production.

Customers see their products improve because they come from the sintering oven almost finished. Simpler assembly, consistent quality, and efficient complex builds result.

At higher volumes, costs decline. MiM limits machining and scrap. Partnering with AMT supports steady supply and easier supplier management globally.

A snapshot of parts, benefits, and outcomes follows. AMT’s MiM process makes these advantages clear.

| Part Class | Typical Materials | Key Benefits | Customer Outcomes |

|---|---|---|---|

| Implantables | Ti alloys, Co-Cr | Biocompatible, fine detail, low secondary machining | Improved implant fit, reduced revision rates, regulatory traceability |

| Surgical instrument parts | Stainless steels | High strength, corrosion resistance, tight tolerances | Improved repeatability, fewer assemblies, stronger sterilization performance |

| Diagnostic housings | 316L SS, specialty alloys | Complex forms, integrated features, cleanroom-ready | Quicker assembly, lower unit cost at scale |

| Automotive fasteners & valves | Maraging steels, stainless | Wear resistance, precise threads, cost-effective mass production | Reduced downtime, lower lifecycle cost, stable supply |

| Sensors & semiconductor fixtures | High-strength stainless, tool steels | Tight tolerances, complex internal geometry | Improved equipment uptime, enhanced positional accuracy |

With AMT, MiM manufacturing and supply come as a complete package. Your project gets tailored design, materials, and finishing. An integrated approach delivers reliability, cost savings, and secure supply.

Sustainability & Efficiency in MiM

Sustainable MiM practices reduce waste and improve yield at AMT. Small components are produced with near-net techniques to cut material waste. Efficient blending and regular checks lower scrap and rework, ensuring steady quality for the medical and automotive sectors.

Using Materials Efficiently is driven by repeatable molding and tight controls. Optimized feedstock/design and efficient cells reduce downstream machining. This strategy keeps costs down and meets the high demands of manufacturers needing large quantities and precision.

Energy reduction comes from fine-tuning debinding and sintering by geometry and takt. Cycle optimization and batch planning cut energy per part. Analyzing the process helps find and fix inefficiencies, reducing overall energy use.

Lean drives yield up and rework down. Visual management, kaizen events, and teamwork resolve issues at the source. That reduces waiting and variability, reinforcing AMT’s reliability as a MiM provider.

Sustainability-aligned supplier partnerships are key. Stable pricing, showing waste reduction efforts, and strong traceability earn trust from medical and automotive clients. AMT’s attendance at trade shows and industry awards highlight its dedication to ongoing improvement and efficiency.

| Area | Practice | Benefit |

|---|---|---|

| Material utilization | Near-net molding, controlled feedstock | Less scrap, fewer secondary ops |

| Waste minimization | Lean cells, SPC charts | Higher yield, lower per-part cost |

| Energy reduction | Optimized debind/sinter cycles | Lower energy per batch, faster flow |

| Operational strategy | Kaizen, visual controls, cross-training | Shorter lead time, consistent quality |

| Customer benefits | Traceability and documented sustainability | Stronger supplier partnerships, predictable pricing |

How to Work with AMT

Engaging AMT begins with a clear, simple sequence. AMT guides buyers from concept to large-scale production. First, align requirements with AMT capabilities. Then follow design review, prototyping, tooling, and production.

How to engage as a contract partner

To start working with AMT, ask about their skills through their website or at trade shows. Typical steps: technical scoping, material selection, prototype testing, then production tooling. Proactive DfM guidance speeds and lowers costs.

Lead times and tooling strategies

Choosing materials and design early helps make tool making quicker. Soft tooling often precedes hard tooling for production. This method makes it less risky for customers needing quick starts or small test runs.

Scalable Production

Production plans scale with your demand. Machining, precision molding, and clean assembly are available. This lets teams work with fewer suppliers and keep everything running smoothly from the first prototype to lots of products.

Worldwide Supply

AMT shows up at big trade fairs like MD&M West and Medical Manufacturing Asia. It reflects robust NA/Asia networks. It helps worldwide clients manage shipping, quality, and rules while finding a reliable parts supplier from Singapore.

Procurement Decision Factors

- Lead-time transparency during tooling and validation phases

- Flexible tooling strategies to balance cost and speed

- Single-source integration to lower supplier count and simplify logistics

- Proven track record via events and references

Selecting AMT brings a team experienced from start to finish. Expect clear timelines, scalable capacity, and a trusted supplier for intricate metal parts.

Wrapping It Up

In Singapore, AMT is known for leading MiM expertise. Since 1996, it has made high-quality mim components. Medical, automotive, semiconductor, and industrial sectors are supported.

The company is praised at events like Medical Manufacturing Asia 2024 and MD&M West 2025. The IVAM Marketing Award Asia 2024 also highlighted its excellence. These awards show AMT’s commitment to quality in the mim manufacturing field.

AMT provides one-stop execution, DfM support, and robust traceability. As a result, it’s a trusted partner for scalable, reliable outcomes. Firms are encouraged to explore capabilities, request DfM, and plan scaling.

AMT is an excellent choice for reliable MiM parts supply. It has the expertise and resources needed for challenging, large-scale metal component projects. Contact AMT to reduce cost, improve quality, and accelerate market entry.